-

Leo Yu

Добро пожаловать в мой магазин. Я рад вам обслуживать. Не стесняйтесь задавать мне любые вопросы.

Leo Yu

Добро пожаловать в мой магазин. Я рад вам обслуживать. Не стесняйтесь задавать мне любые вопросы.

Ваше сообщение превысило лимит.

Новости компании

As an important part of the charging cable connecting the charging pile and the electric vehicle, it is crucial to ensure its waterproof performance. Waterproof performance directly affects the safety and reliability of charging cables, and also extends their service life.

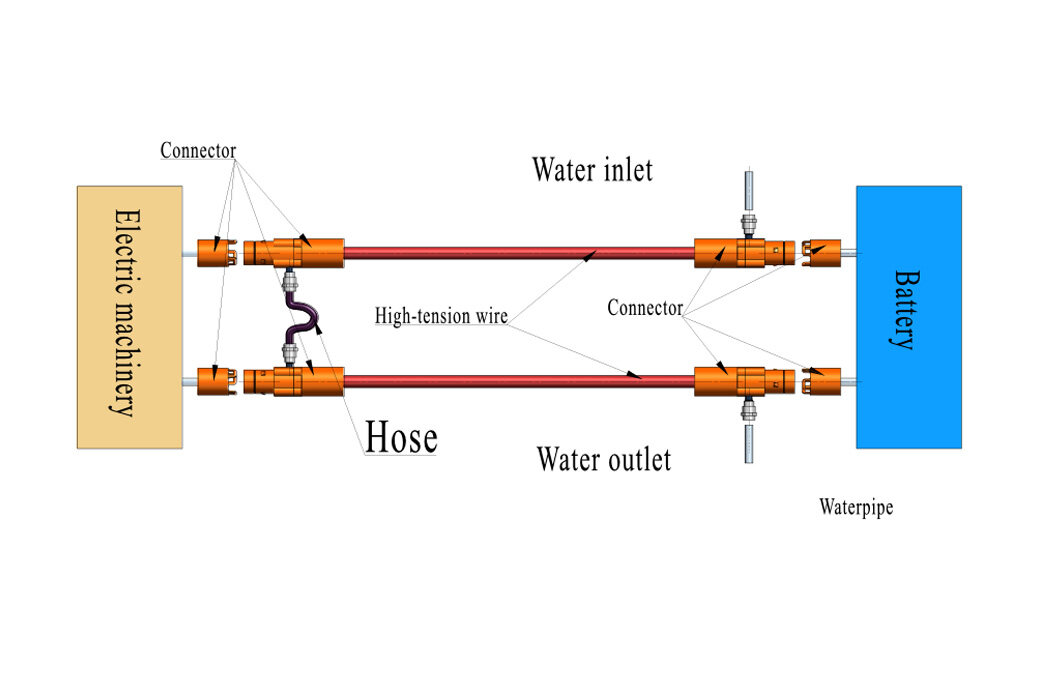

There are various methods and measures to ensure the waterproof performance of charging cable. First of all, the connection part and interface of the charging cable should be sealed to ensure that water can not enter the internal cable. Common sealing methods include rubber seals, waterproof adhesive, etc., which can effectively prevent water penetration. Secondly, materials with good waterproof performance should be selected for the outer layer protection of charging cables. Common waterproof materials include waterproof rubber, waterproof plastic, etc., which can effectively isolate external moisture.Third, the insulation layer is also an essential part of the waterproofing role, the insulation layer material of the charging cable should have good waterproof performance, which can effectively prevent water penetration. Common insulation materials are TPE, PVC, etc., with good insulation and waterproof. Furthermore, the charging cable should have a certain degree of water pressure resistance, able to withstand a certain water pressure under the working environment. Through reasonable design and material selection, it ensures that the charging cable can work normally in a humid environment. Finally, in the production process, the charging cable needs to undergo strict waterproof performance testing, with data and experimental results to ensure that the cable meets the relevant standards and requirements. Common test methods include water pressure test, water immersion test, etc., which can evaluate the waterproof performance of charging cables.

The waterproof performance test of electric vehicle charging cables is an important part to ensure that the charging cables can work properly and be used safely in wet environments. The test usually includes the following aspects:

Waterproof rating test: Through the waterproof rating test of charging cables, the waterproof performance of charging cables is evaluated under different water pressure and water depth conditions. Commonly used waterproof rating test standards include IPX7 and IPX8 ratings, of which IPX8 rating indicates that the cable can be immersed for a long period of time under a specific water depth without damage.

Electrical Conductivity Test: Tests the electrical conductivity of charging cables in humid environments to ensure that the cable's conductors and connectors are able to properly transmit power without increased resistance or power leakage due to humidity.

Insulation test: test the insulation performance of charging cables in humid environments to ensure that the insulating materials of the cables can effectively isolate the conductor and the external environment to prevent power leakage and cable damage.

Durability test: test the durability and stability of the charging cable by simulating the conditions of long-time use and vibration and temperature changes in a humid environment to ensure that it can maintain good waterproof performance for a long time in actual use.

Ensuring the waterproof performance of charging cables requires comprehensive consideration of design, material selection and testing of various factors. By testing the waterproof performance of charging cables, it can ensure the safety and reliability of the cables in humid environments and improve the user experience and charging safety.As an excellent EV charging cable provider, OMG' has been an industry leader in product testing and certification, and has obtained industry certifications such as TUV, CQC, DEKRA, IEC62893, EN50620, UL2263, JCS4522 and PSE, etc. OMG' has always been committed to providing professional customized services of cable solutions to meet the different specific needs of customers. Only under strict quality control and standard requirements, the waterproof performance of charging cables can be effectively guaranteed to ensure the safety and reliability of the charging process.