What do we need to do to ensure charging safety when charging electric vehicles?

The charging safety of electric vehicles has always been concerned by the market, the following is to focus on charging safety from several aspects of the charging process:

First, ensure the charging environment is safe. Charge your electric vehicle in a clean, dry place, as far away as possible from any water source or flammable materials. Electric vehicle charging cables need to have good water and oil resistance, corrosion resistance, acid and alkali resistance and other special properties.

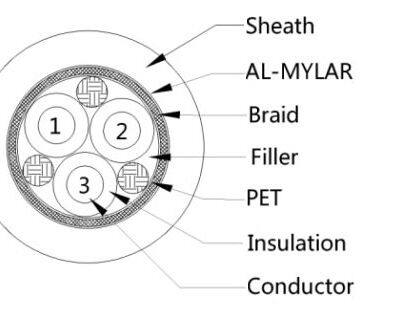

Next, check whether the charging equipment is damaged. Check the charger and charging cable for signs of damage, such as broken or loose cables, before each use. Electric vehicle cables have good mechanical properties, wear-resistant, drag-resistant, etc., adapting to a variety of complex charging environments.

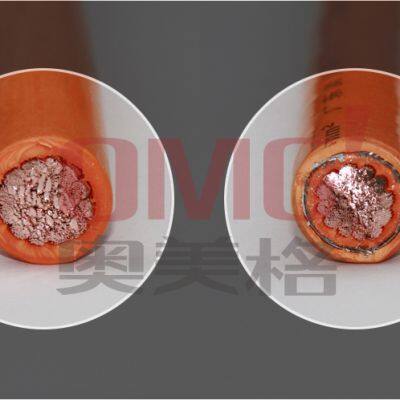

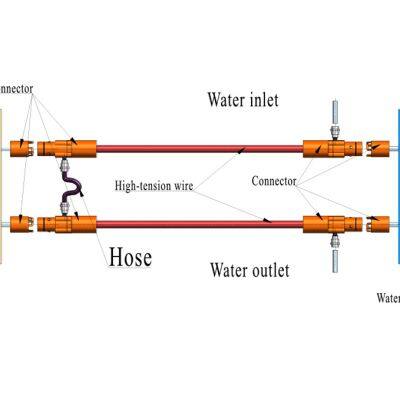

And the devices get hot when charging, so don't cover them with anything to avoid overheating.Also don't touch the battery or plug and unplug the charging device directly. Liquid-cooled charging technology can be used to reduce the excessive buildup of charging heat and realize real-time effective heat dissipation, which can carry high-current rapid charging. Finally, charging systems need to be checked and maintained regularly to ensure they are in good condition.

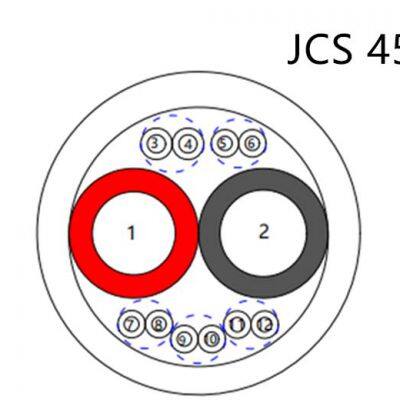

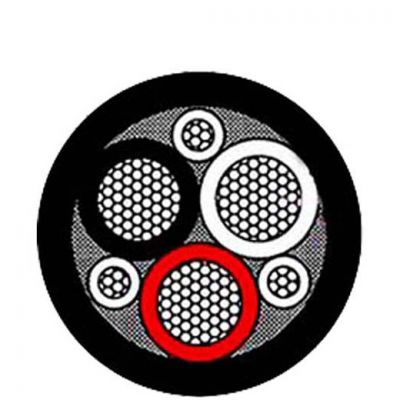

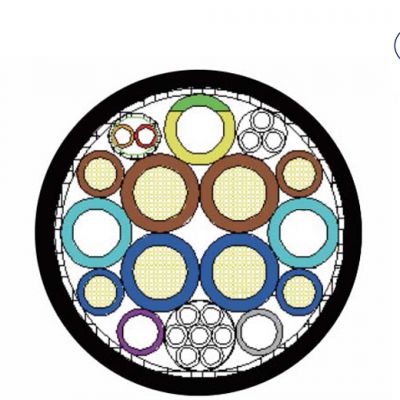

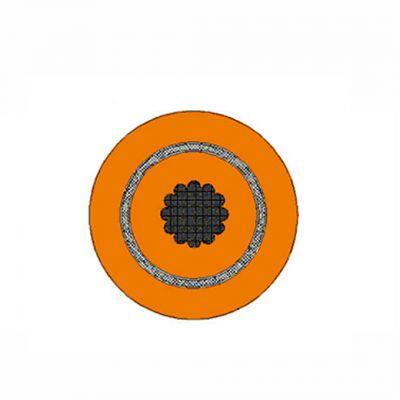

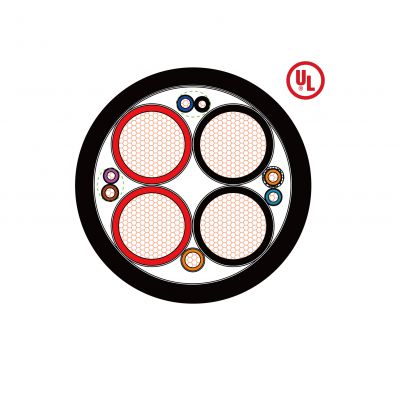

OMG' is committed to be the world's first-class new energy charging application technology provider, with experienced technical team, focusing on cable mechanical performance and special performance testing. We have always been adhering to the "green innovation" R & D concept, the specific needs of customers into practice, to provide customers with customized, standardized charging application technology solutions. Electric vehicle charging cables are an important part of new energy charging equipment, and OMG's electric vehicle charging cables meet the European standard EN, IEC,UL, JCS, PSE, CQC and DEKRA certificates. It has high flexibility, bending radius less than 5D; acid and alkali resistance, abrasion and tensile resistance, crush resistance, crack resistance, UV resistance; bending resistance of more than 50,000 times; good flame retardant properties; all materials used are in line with RoHS 2.0 & REACH environmental standards. With the continuous development and improvement of new energy charging technology, it can better guarantee the safety and reliability of the charging process, which will help promote electric vehicles will become the mainstream transportation in the future, and make an important contribution to the construction of a clean and low-carbon society.

Recently Posted

-

"Small wire diameter, high current"|OMG'European standard oil-cooled charging

December 13, 2024With the rapid development and popularization of electric vehicles, oil-cooled charging cables have attracted much attention as an Read More

Read More -

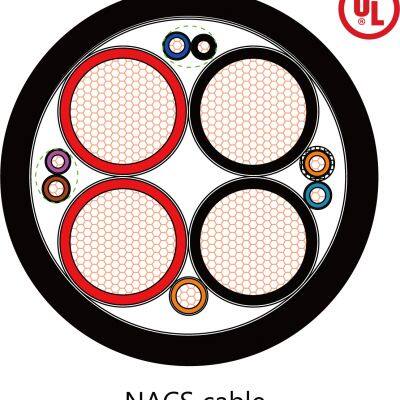

More lightweight design|UL certified charging cable

December 13, 2024OMG'UL certified charging cables include conventional products and the new NACS series of off-standard nylon constructions, wi Read More

Read More -

Understanding the European Standard Charging Cable Designation

December 13, 2024Electric vehicle charging equipment needs to have industry standards for its safety and reliability to do constraints and guarante Read More

Read More -

How to choose the home charging equipment

December 13, 2024In today's society, electric vehicles are becoming more and more popular because they are environmentally friendly, energy eff Read More

Read More